Lace, lots of it, in bright, zesty colours or neutral tones, simple bridal white or black, or even blood red, has become the crucial common denominator of fashion.

In Pictures: Manufacturing Lace

A peek inside the Sophie Hallette lace factory, near Calais in northern France.

In a season where more or less anything goes trendwise, lace pulls it together. Lily Allen went for lace on her wedding day. So did Kate Moss, in a vintage version by Galliano. The Duchess of Cambridge is the most obvious example, but more on that later.

However, lace is not just for weddings.

It can be big. It can be loud. It can be bold. Lace was the undisputed star of London's recent graduate fashion catwalks, with students such as Emma Rose James of Central Saint Martins using industrial Triacetate, a Japanese rayon, and fine Leavers lace from the French lace maker Sophie Hallette, to create something radical.

Lace inevitably bags the finale during haute couture. The current ready-to-wear collections from Christopher Kane - who used flouro green and candy-floss-pink lace - and Erdem, whose red lace Prom dress has been copied by the entire high street, are testimony to its relevance as a modern high-fashion fabric, too.

But perhaps the chief reason for its phenomenal comeback has a lot to do with the quaint, old-fashioned way it's made.

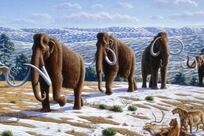

Contrary to fast-fashion practices, lace - in high-end production at least - cannot be rushed. To find out why, I visited the most wonderful lace factory in the world: Maison Sophie Hallette, a French company that can trace its roots back to 1887. It is considered the "Willy Wonka" of lace-makers.

Remember Prada's "Mrs Danvers" black lace collection of 2008? Hallette made it. Clients include superbrands such as Chanel, Givenchy, Erdem, Christopher Kane, Valentino, Zuhair Murad, Christian Dior, Dolce & Gabbana, Versace, Burberry and Alexander McQueen as well as the lingerie brands La Perla and Agent Provocateur.

The factory is in Caudry, a small, sleepy village, surrounded by poppy fields in northern France, and when I arrive at lunchtime on a Monday it seems unusually quiet.

I would have found a quite different scene a week earlier, the marketing director, Maud Lescroart, tells me. She is the granddaughter of Etienne Lescroart, a tulle-maker, who bought the company from the founding Hallette family in 1952.

Following a certain delivery of 120 metres of silk tulle woven with shamrock, roses and lilies to Sarah Burton, the Alexander McQueen designer, the factory had been working at full capacity.

Yes, ever since Sophie Hallette supplied the lace "canvas" to the Royal College of Needlework craftsmen who then cut out the scalloped décolleté sleeves and train for Kate Middleton's wedding gown, it has gone from being the fashion industry's best-kept secret to a national and international household name (the French gossip magazine Gala devoted a five-page feature to the company).

I soon learn that "full capacity" in a high-end lace factory, where time is frozen in the mid-19th century, is hardly comparable to clothing production lines in Asia, however.

"Our pace is the Leavers loom," explains Lescroart, who gives me a tour of a series of aircraft-hangar-sized rooms housing archaic machines the size of articulated lorries, descendants of the original Leavers looms and dating back in many cases more than 100 years.

What strikes me, on seeing men working machines that might otherwise have been gathering dust in textile museums, is their passion for a laborious job involving feeding several thousand miles of thread through 5,000 noisy shuttles surrounded by 12 tons of juddering cast iron. One loom can produce only 60 metres of lace a day, and it can take three people two months to set one up. More than 70 metres of thread are needed to make 12 metres of lace.

I'm not sure what health and safety officers might say about machines that seem to demand the constant eye and nimble hands of trained artisans, but I stand well back and listen to their "music": the mechanical clunking and hissing of metal arms shooting out to gather skeins of weblike thread, knotting and weaving them into 90cm widths of lace.

"It's not for nostalgic reasons we keep them," Lescroart explains. "Nothing has ever been designed that produces more beautiful lace than a Leavers loom. The little irregularities give lace its character. It is fallible by design."

Lescroart also discloses that the company had "no idea" a pattern revived from 1958 would become part of fashion legend, but admits that it was just hours after the royal nuptials that a loom was being prepared to make more of "Kate's lace".

There is another reason why Sophie Hallette was the appropriate choice of lace-maker to a probable future queen of England.

"All our looms are British and always have been," says Lescroart, and tells the story of how during the Industrial Revolution in England, export of the new machinery was banned. "Leavers looms were smuggled in boats, destined for Valenciennes. They arrived at the port of Calais, but never got further than Caudry, which had a heritage of linen makers."

Eugene Hallette founded his company with six looms in 1887 in Caudry, where it quickly became the third-largest of 170 lace-makers. It remained within the Hallette family until Etienne Lescroart bought it in 1952 and opened a Paris office, which he named Dentelle Sophie after his niece, born the day before (dentelle is French for lace). The combination of names stuck.

"My father, Bruno, who took over the firm from my grandfather, Etienne, was particularly proud of a loom dating back to the early 20th century which had taken him 10 years to refurbish. Etienne himself invented a device to stop the machine when the thread breaks. The loom that makes one of our best-selling lace patterns dates back to 1902."

All lace is created in its natural ecru colour, then hand-dyed in a process literally translated as "giving birth", which takes days.

Secrecy is tight on the factory floor. I spy one giant vat churning out spaghetti-like strips of spinach-green lace. Another contains aubergine, pink and gingery orange lace, the colour of festival dip-dye hairdos. Could this be Burberry or Chanel's winter lace collection? I ask myself.

I find Romain Lescroart, the third-generation Lescroart chief executive, sitting in his marble office surrounded by top-secret swatches of fabric. "We're working on requests for gilded lace woven with semi-precious stones and Swarovski crystals," he says, showing me featherweight, hand-painted lace interwoven with ostrich feathers and jewels.

This third-generation lace maker, like his father and grandfather, continues to experiment and twist the rules of lace.

"Lace makers must be explorers and artists," he explains. "The beauty of the Leavers looms is that we need never stop experimenting."

Last year Sophie Hallette's exports rose by 60 per cent, which accounted for 80 per cent of turnover. It now has customers in 60 countries, including some in the Middle East - "countries that traditionally want the best in innovation and luxury," he says.

"Usually the popularity of lace goes in waves," he tells me. "It usually takes seven years before it hits a high point then plummets. This is the third year... we've been waiting for a dip but we just seem to get busier and busier."

Karen Bonser, Topshop's joint head of design in London, said the company had used Sophie Hallette often, for the Kate Moss range and for Unique. The trend, she said, appeared to be strong. "Going forward for autumn/winter, lace is becoming even more spectacular: embellished, embroidered, studded and layered with colour underneath."

Romain Lescroart, too, remains confident his precious commodity won't go out of fashion: "My father used to say lace is like salt," he said. "You can live without it but life becomes dull."