Etihad Airways raised the stakes of luxury travel in May by introducing a US$20,000-a-ticket, sky-high hotel suite called The Residence.

To concoct this new offering, the Abu-Dhabi based carrier had to tear up the floor plans of the Airbus double-deck A380 and the Boeing 787 Dreamliner. The National spoke with three of the project’s designers to find out how they went from blue-skying to reality.

In Part One of the conversation, with Mike Crump, a partner and director at London-based Honour Branding, explains the seven stages of the project, from cultural immersion through vendor support.

Then in Part Two, Adam White, a director of London-based Factorydesign, and Nigel Lawson, a director of London-based acumen, join the conversation as we delve into the details of how it got done.

Part one

Walk me through the creative process of this project.

Mike Crump: There were several stages to the project.

First, the immersion stage: Etihad Design Consortium (EDC) spent some time immersing themselves in the culture of the Emirate of Abu Dhabi and the 2030 vision. We also spent time understanding Etihad’s current product and achievements, and the strategic intent of the airline for the future by interviewing key stakeholders and [the] CEO.

Second, the research and co-creation stage: Part of our role as the EDC was to advise on the innovation process and this started by putting the customer at the heart of the process. EDC brought in Promise Communiscape, a company to manage a series of unique co-creation research workshops with customers in four cities: Abu Dhabi, London, Sydney and New York. These co-creation workshops called “Big Talks” also included Etihad staff and members of the EDC design team and together they dreamt the future of air travel in the two-day event. Customers spent time building and creating their ideal flight and cabin environment, enabling the team to get underneath their core needs and aspirations.

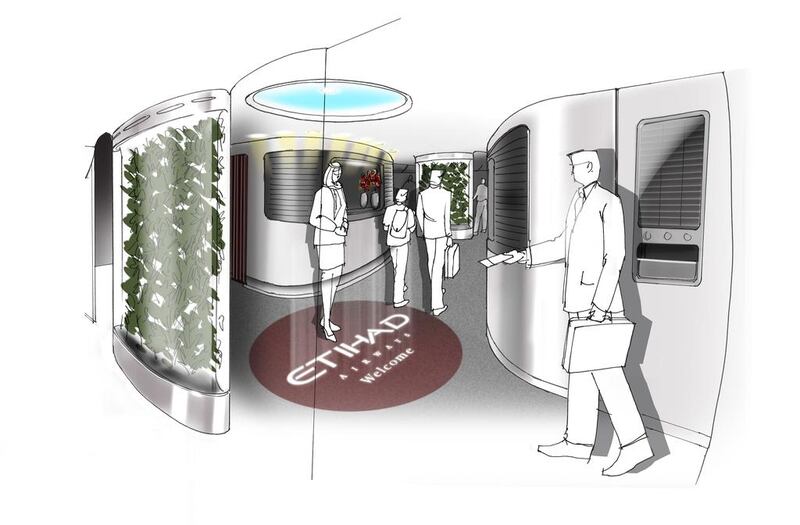

Third, the strategic platform stage: With the research and immersion complete, Etihad defined the commercial parameters and asked the EDC to create a strategic platform that would help to define the guest experience onboard and give direction to the design of the cabin interior products. The airline benchmarked the best hotels, rather than other airlines, and thus the strategic platform created was a “luxury boutique hotel with Arabian Modernism”.

Fourth, the concept generation stage: The concept generation stage allowed the team to explore potential solutions and new ideas. Informed by the customer research and building on the luxury boutique hotel, the team were able to create a wide variety of concepts for the cabin. Cardboard sketch mock-ups were used in this stage to prove some of the concepts would have the right space and ergonomic considerations. Once the concepts were narrowed down by Etihad, the EDC developed the key concepts into wood and foam spatial mocks that could be used in further customer research.

Fifth, the concept development stage:

Once the preferred designs had been chosen, the team were tasked with refining and developing the concepts to ensure they met the customer requirements and could be manufactured. Further mock ups were produced to validate the ergonomics and the packaging and integration of mechanisms and technology. The team produced full-size sections of the A380 and B787 cabin interior at a secret warehouse facility in west London, and further styling mock ups were produced in the desired fabrics and materials to bring alive the final look of the cabin interior. The mock ups were used to gain senior management approval at Etihad and also were used to brief the vendors and manufacturers, from all over the world, that would eventually produce and manufacture the new products.

Sixth, the detail design and engineering stage: The EDC worked closely hand in hand with the manufacturers and vendors as they translated the design intent of the concepts into production data. The EDC produced further mock ups to finalise the styling and the final colours, trim and materials that would be used. EDC supported the vendors through the technical design as they engineered the products for manufacture whilst maintaining the vision and integrity of the product. The vendors then would produce final prototypes as the technical and styling details are finalised in which Etihad would sign off.

Seventh and final stage, the production liaison and implementation: The final phase is supporting the vendors as they prepare the designs for manufacture –supporting them with troubleshooting and final design amendments as first production samples are produced for approval and sign off.

Part two

Where did you get your ideas from?

Mike: I think the ideas were born from how you design a boutique hotel. Everything shouldn't be the same. We asked ourselves, why can't the first class seats all have different colours? This makes an individual feel. These things really pushed the boundaries and what we managed to do was to get three colours of leather and seat fabrics and cushions, so each suite would have a different colour. That's the ultimate luxury, as people want something different or something unique. We also wanted to create a niche lighting to be unique to the Etihad brand. We were inspired by the [planned] Louvre Abu Dhabi ceiling, which is really inspired by sitting under the date palms in an oasis. It's the mix of the shade and the sun that you get and we managed to do that. We worked with Airbus to change the ceiling pattern and use projection LED light.

Adam White: We spent the first three months visiting Abu Dhabi regularly. For the first three months, we didn't let ourselves pick a pen or pencil to begin sketching. We spent our time immersing ourselves in everything that we can learn about Abu Dhabi and the greater region that Abu-Dhabi was based in. We built out a library of iconic things that you see when you visit the region, so that the design and the ideas that we had had a language from the very start that would reflect Abu Dhabi as you visit it these days.

Were there any surprises following the surveys?

Mike: Some of the early ideas of The Residence, customers said they would want a separate seat and a separate bed that they would sleep on. Like a hotel room or at home, where you have a piece of furniture for a different function, they were questioning why can't I do that on an airplane, and understandably it needs more space. They were talking about more comfort, and make it feel more homely and more residential.

Adam: I think one of the things that left a lasting impression on us was, globally speaking, how airline travel in premium classes had become more sophisticated than it was one decade ago. One of the virtues of the A380 is the two decks and because the decks cannot be shared between the passengers because of the stairs. We thought that the next level of travel for premium passengers would be almost a private jet. The design had essentially put a private jet on the top of a best economy class experience. But when you board upstairs it really feels like you are boarding on another aircraft all together- essentially a private jet.

Nigel Lawson: Privacy. Privacy was high in the agenda. The Emirati and the top local culture wanted privacy.

Let’s talk about the challenges.

Mike: The biggest challenge was the scale of the project. Etihad from the beginning realized that one agency couldn't manage the agenda that they put forward – to be the best in the world. They quite rightly put the EDC to say [agencies could work together] to challenge everything onboard of an aircraft. The result was the most customized A380 or commercial aircraft that has ever been received. We not only challenged the seating environment, but everything from the galas to the entrances to the bathrooms and the lighting onboard. The challenge was the sheer volume of design and innovation and the coordination - to make it look cohesive - like it is from one organization and one brand. It was three of us on the phone - three representatives of the businesses of EDC—but the fourth very significant member of our team was Etihad itself. We had enormous support from Etihad.

Adam: We pushed Airbus very hard. It was very challenging in lots of respects, for example air flow, direct view, and ceiling configuration. We worked with Airbus from the beginning to understand the limitation and the challenges, but we had to challenge them and work with them with engineering solutions. We didn't want to come out with a solution that couldn't be implemented. We worked very early on on the concept and getting them involved to understand what are their specification issues. For a wide-body to have a single aisle challenges anything anyone had done before. It needed rethinking. It wasn't something outrageous that could never be delivered. It was something that only challenged the status quo.

Nigel: I would share Mike's view. The design process, because nobody had ever approached a commercial aircraft with the rigor that Etihad wanted. The first half of the project was a huge challenge to really think outside the box and create a very customized experience for the guest. The second half of the project was devoted to the second enormous challenge to deliver that vision and working with Etihad and all the suppliers and the aircraft manufactures to turn the designers' dreams into a reality. There have been many aircraft launched that have looked fabulous as ideas, but a huge challenge to deliver those ideas.

And the biggest challenge?

Adam: For Factorydesign there were two major challenges, the first in the early days of the programme and the second throughout the later phases. Challenge one was to look beyond the minutiae of aircraft manufacture and function, to create an innovative vision that translated into real products, like radical galleys or three-room suites, which truly represented the future for Etihad. The latter challenge in the programme was to work extremely closely with the manufactures of all parts, the galleys, toilets and indeed the aircraft themselves to deliver the dream. Designers have spent a fortune creating fabulous concepts but we had to create a new, ground breaking reality. This involved a high level of commitment and trust between us, Etihad and all the suppliers, where everyone involved contributed their expertise and took time to listen and learn from each other.

selgazzar@thenational.ae

Follow us on Twitter @Ind_Insights