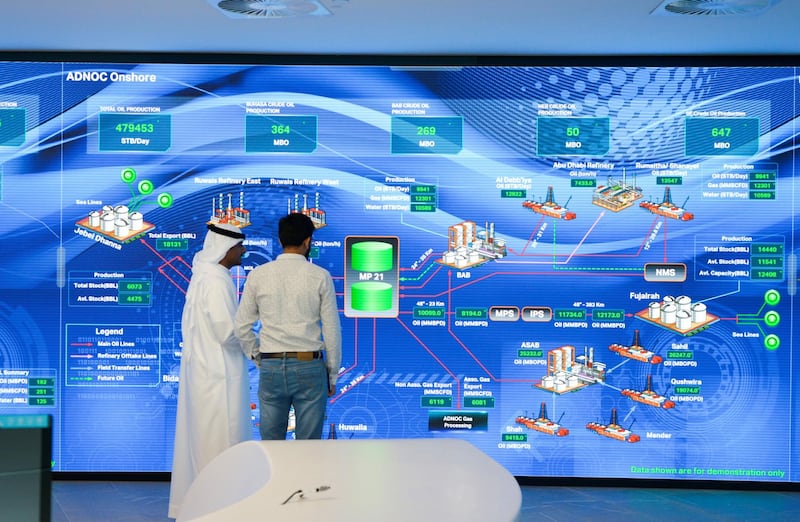

Adnoc’s digital command centre has generated over $1 billion (Dh3.67bn) in business value and allowed the state-owned oil company to maintain operations and respond swiftly to market dynamics throughout the coronavirus pandemic, according to the company's senior vice president of digital.

Since it opened in early 2018, the Panorama Digital Command Centre has provided cost savings and improved production efficiency with "an investment of less than Dh50 million", Abdul Nasser Al Mughairbi told The National.

“Technology is doing all the work of connecting us together,” he said. “The importance of embedding digital technology in businesses has never been greater and Adnoc’s continuous investment in digital transformation over the last three years allows us to be more resilient.”

The energy industry is facing its biggest shock in 70 years from the coronavirus pandemic, according to the International Energy Agency, which forecasts global energy demand will fall 6 per cent this year, nearly seven times the rate of decline following the 2008 global financial crisis.

The UAE, Opec's fourth-largest producer, accounts for 4 per cent of global oil production, with state-owned Adnoc responsible for much of that output. But crude producers are looking to roll back record production as travel restrictions and work-from-home orders curtail demand.

"The calculation of economic survival has become extremely complex in this matter of wafer-thin margins," The National's energy columnist Robin Mills wrote last month. Operating costs, transport costs to market, the costs of stopping or restarting production and oil quality are all factors to watch, he added.

To that end, Adnoc’s Panorama is built to “monitor every molecule of hydrocarbon”, according to Mr Al Mughairbi.

The command centre, located at Adnoc’s headquarters in Abu Dhabi, is now being accessed remotely by employees through a secure connection amid Covid-19, providing real-time information across Adnoc’s 14 subsidiary and joint venture companies and using artificial intelligence and data analysis to anticipate disruptions and optimise production.

The state oil major has developed in-house capabilities of data gathering and reporting to reduce software and third party costs across the company. Hydrocarbon production reports can be generated in real time, with all 14 of Adnoc’s companies feeding into a single system, linking all 56 control room sites covering offshore production, gas processing, petrochemicals, refining, onshore production and condensate, according to Mr Al Mughairbi. Cost savings and value generated by Panorama is calculated on a monthly basis, he said, which brought Adnoc to the $1bn figure.

Panorama is one of several digital transformation initiatives undertaken by Adnoc. Chief executive Dr Sultan Al Jaber laid out his plans for the company’s tech-driven future at Abu Dhabi International Petroleum Exhibition Conference (Adipec) last November.

"The era of digital disruption is just beginning for the industry and will only gather pace over time. Yet, the oil and gas company of today can be a winner tomorrow, if it operates at a lower level of cost and a higher level of performance," he said.

The pandemic is now accelerating Adnoc’s digital transformation strategy, according to Mr Al Mughairbi.

“The Covid situation has shown us we need to roll out [technology] at a much faster pace,” he said, with further investments planned for remote assistants, wearable technology and remote monitors, like drones, to reduce contact between people and the number of site visits required.

A bespoke health, safety and environment information system is currently being built into Panorama by harvesting information from millions of data sensors to give instant, real-time readings across its facilities.

Separate from Panorama, Adnoc is investing in implementing blockchain across every step of extraction and production of hydrocarbons. Blockchain will provide a transparent and unchangeable record of how much each molecule costs to extract and turn into a product, how long it took to produce and the CO2 it generated, contributing to lowering production costs and providing a record of Adnoc's carbon footprint.

At first, Adnoc planned to partner with IBM on all of its blockchain requirements. Today, Mr Al Mughairbi said they have in-house talent and access to open-source materials to pull off aspects of its blockchain programme at a much lower cost, while still partnering with IBM.

Ultimately, the use of technology and embracing digital tools “will differentiate the Adnoc hydrocarbon molecule” from the rest, he said.