NEW YORK // The microchip maker GlobalFoundries expects to reach full capacity of producing 60,000 wafers per month in its New York fabrication plant by the end of next March.

The company, which is wholly owned by Abu Dhabi's Advanced Technology Investment Company (Atic), is building a 90,000 square feet extension to the fabrication cleanroom, the place where silicon wafers are treated, following strong demand for the 28 nanometre (nm) nodes it produces.

Construction on the extension began last September and is expected to be completed by the end of this year. Turner Construction has been contracted to build the extension. The company also worked on Dubai's Burj Khalifa, the world's tallest tower.

The fabrication plant, which has been online since early 2012, produces 300mm silicon wafers on which nodes are chemically etched.

Strong global demand for silicon chips used to power smart devices has enabled GlobalFoundries to become the fastest-growing chip manufacturer in the world, according to IC Insights, which conducts market research analysis for the semiconductor industry. It estimated a 31 per cent growth in revenues for the company in 2012. Last year GlobalFoundries grew 15 per cent rise in production. The company is targeting profitability by 2015.

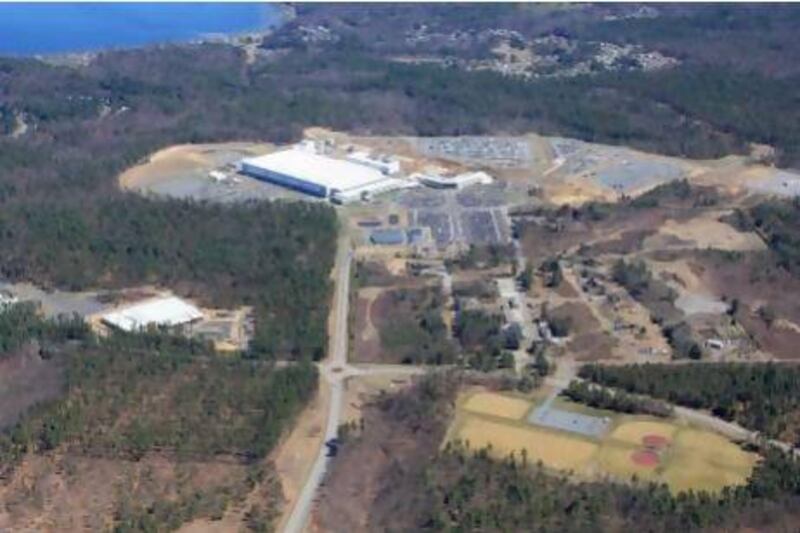

GlobalFoundries occupies a 223-acre site in the Luther Forest Technology Campus in the state of New York, where it broke ground on its fabrication plant in July 2009. The plant has created 2,000 direct jobs and more than 7000 indirect jobs and has become an economic success story for the state, attracting three visits from the US president, Barack Obama.

What began as a US$4 billion project has grown to one that will be worth some $8.5bn once construction of the extension and a separate Technology Development Centre (TDC) is completed towards the end of next year. The TDC will become GlobalFoundries' main research and development centre and will also have the capability to produce 28nm nodes. The site is set to create an additional 1,000 jobs.

Talks are ongoing on building a second fabrication plant in the area if demand warrants it.

"We are doing the preliminary work. It is all open-ended discussions that are taking place. We have started the design work and estimates and it could cost $10bn to $12bn, but it depends on whether the customer need is there for it," said Travis Bullard, a spokesman for GlobalFoundries.

Plans to open an Abu Dhabi fabrication plant are still on hold. Atic had originally planned to complete construction of the plant by 2015, but the global economic downturn and uncertainty halted construction. Atic is in the process of assessing the market before it begins work on the local fabrication plant.

Atic is wholly owned by Mubadala Development, a strategic investment company owned by the Abu Dhabi Government, and was founded to help diversify the emirate's economy and create jobs.