As the ever-expanding global population puts pressure on farmers to make their crops go further, a pioneering planting method that uses little water and no soil could soon revolutionise the way we grow our food. John Morrish reports. Agriculture is growing up - literally. With the world's population growing rapidly, and fertile land in increasingly short supply, thoughts are turning to the possibility of "vertical farming".

The idea was originally mooted in 1999 by Dickson Despommier, a professor at Columbia University in New York City. He envisaged a network of 30-storey urban tower blocks filled with crops, capable of feeding thousands of people. In the years since, much thought has been devoted to the idea, but nothing practical has happened, not least because Despommier expects his farms to cost hundreds of millions of dollars.

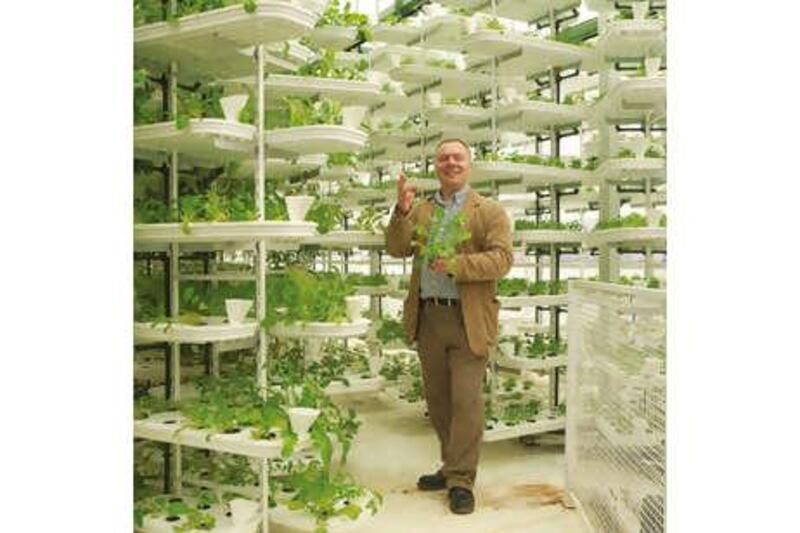

And yet, every journey starts with a single step. In the case of vertical farming, that step has been taken in Paignton, south-west England, where what is claimed to be the first vertical farm in the world is producing leafy green vegetables, but for feeding animals not humans. The zoo there is piloting a system called VertiCrop, created by Valcent EU Ltd, the UK-based subsidiary of an American company. This modest beginning could be the start of a revolution in world farming and is important for areas where water and soil are in short supply. A VertiCrop farm does not use any soil, and its water usage is just five per cent of that of traditional agriculture.

The Paignton "farm" consists of up to 11,000 plants on plastic trays, stacked eight deep to a height of 3m on 70 "rigs". These move slowly around on a conveyor system that gives all the plants equal access to light and ventilation. With a floor area of 100sq m, the Paignton farm is a half-size, half-height version of a standard VertiCrop module. In the real thing the plants would be stacked 6m high, making it hugely efficient. It is claimed that a square metre of VertiCrop can yield as much produce as 20sq m of a flat field or between 4-6sq m of a conventional greenhouse.

The zoo took on its pioneering role when Kevin Frediani, the curator of plants and gardens, arrived from Amsterdam's Botanical Gardens in 2008. He wanted to feed the animals with crops grown on site, enrich their lives (even carnivores such as big cats like the smell of herbs) and demonstrate the principle of sustainability. But space was a problem. "How do you grow food when you are in competition with the animals on the site?" he wondered.

He came across Valcent when the company attended an environmental exhibition at the zoo. Its stand included an 18cm-high model of a VertiCrop growing lettuces. Frediani was told he could see a pilot project at the Valcent headquarters in Cornwall in six months. Instead, he persuaded them to build its pilot scheme at the zoo, where it could start doing a useful job from day one. The zoo funded it and pays the running costs. Valcent provided the system, including the computer and filtration system, at a cost of about £200,000 (Dh1.1million) "If the pilot failed," says Frediani, "I could have always turned the building into a butterfly house."

It has not failed. The system was installed in September 2009 and started producing almost immediately. The zoo buys in Dh1.1million worth of fruit and vegetables every year. Frediani's target for the first year is to produce Dh110,000 worth of animal food, including lettuce, spinach, Swiss chard, giant red mustard, rocket and herbs. The plants are grown hydroponically (in water), and the system's computer programme allows it to feed different plants with different nutrients as they are irrigated three times a day. All the waste water is filtered, its nutrients measured and then topped up as necessary, and then recycled into the irrigation system. A control panel allows the part-time agricultural technician who runs the system to see what is happening and make adjustments.

"There is no wastage," says Frediani. "And nothing goes out to harm the environment." No pesticides or herbicides are used. And electricity usage is modest: Frediani says that in one day the system uses no more power than a domestic computer uses in a week. Valcent has greater ambitions for its system. Its business development director, Tom Bentley, promotes its suitability for many environments around the world. "It grows food or produce without the need for land," he says. "The system is designed around 200sq m modules, but in practice we expect commercial growers, cities and governments to build very large installations using multiple module-covering hectares."

In the Middle East, the system could be used to reduce imports and enhance food security by enabling growers to produce crops all year round much more cheaply than in conventional environment-controlled greenhouses. "By going vertical you massively reduce costs because you reduce the amount of building you need to grow the same amount of product. And the energy costs needed to run it are much lower than with a conventional horizontal production system."

He estimates both capital costs and energy costs at less than half those of conventional hydroponic greenhouses producing the same amount of crop. "If I was looking at food security," says Frediani, "and I was in a desert environment where water was a limited resource and soil was a limited resource, then VertiCrop would be an ideal solution for growing fresh fruit and vegetables adjacent to cities."

He would, he says, put the structure underground, keeping the crops cool, and use solar electricity to power the system's lighting, filtration and computer. Vertical farming offers the prospect of growing crops in cities, on rooftops for example, or on brownfield sites where residential development is not possible. Farmers could harvest, and deliver to towns within half an hour, with huge nutritional benefits. Other possibilities would be for a restaurant to install a small system to harvest vegetables and serve them straight to table, or to build a system alongside a supermarket.

Bentley has been in Abu Dhabi talking to potential customers, including the university and the developers of the Masdar eco-city, but he is keeping those discussions under wraps. Both Bentley and Frediani see vertical farms playing a role in feeding the world sustainably. Frediani notes that the arrival of an extra two billion people by 2050 will require an area the size of Brazil to go under the plough. "This isn't going to be the answer to this," he says. "It's certainly not going to feed two billion people. But it will take some of the pressure off."